It's time to finish off the cockpit seat backs.

The storage lockers are undercoated.

Three coats of "Botecoat" white paint completes the seat back storage area.

I give the inside face of the 6mm ply seat back three coats of epoxy and the forward storage section is painted. The area is ready to be closed up now (almost)

The seatbacks are glued in place...........

I use clamps and temporary screws to hold the seat backs in situ until the epoxy sets.

After cleaning up the seat back sides flush on top and before installing the last piece (the seat back deck) While I had access, I decided on another mod......

This mod is electrical, and I considered a number of things:

Firstly, I screwed cable ties that are in a loop to secure the electrical wiring through the locker space.

The very aft looped cable tie was quite the challenge. I improvised with some very long drill bits, very long screw drivers and blue tack to hold the screws onto the bit. It would have been much more difficult if the seat back deck was glued in.

I also wanted to be able to light up the storage area, have USB DC power supply for mobile phones and iPad, switches and be able to see the current state of voltage.

So, in the forward section of the port storage locker, I designed a small panel that would house all the items pictured below.

The area is protected from the elements, visual, provide easy access to the USB plug and switches and have the ability to be removed when required.

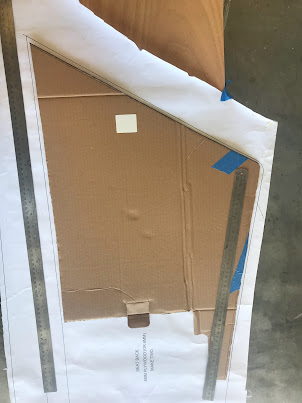

So firstly, I knocked up a cardboard template.

I trimmed and fitted the template several times before I obtained a neat finish.

Here is the final template held together with masking tape.

The template sections are traced onto 4mm ply, hot glued together and trimmed to fit. Epoxy fillets are laid on the inside to hold the unit together.

Holes are cut for the meters and switches and the unit given a protective coat of epoxy.

Here are some more views.

This view has a great background.

An aluminum angle is used to secure a courtesy LED light which will be screwed to the very top of the switch section (as shown in pic below). This location will indirectly light up the storage area but not shine directly into my face. If required, it can be modified to a red color for night-time use.

The panel is painted, electrical outlets and two switches installed, one is a spare and the other turns both port and starboard locker courtesy lights on simultaneously.

Wiring is run from the port side lazarette chamber up into the storage area and connected to the panel. I used tinned copper electrical wire, 2mm for the LED lights and 4mm for the power.

Additional wiring is also run from the Port lazarette chamber to the forward storage locker near the aft cabin BH via the 25mm electrical conduit. These wires will connect to the compass NAV light and provide cabin lights and DC power outlets into the main cabin.

Now all the wiring is run and neatly cable tied together it's time to install the panel.

The port seat back top is glued and held in place with weights. Next is the starboard side......that tomorrow's project.